Working Principle

Liquid Nitrogen Dosing Machine is the latest liquid nitrogen dosing machine in China which uses the similar machines abroad for reference. It could control dosing volume accurately, no-container-no-liquid dosing, small size, easy installation and could coordinate with any filling production line. Control system comprises Siemens PLC and touch screen, all pipes adopt vacuum heat-insulated pipes which could ensure minimum consumption of liquid nitrogen and no frosting operation condition.

Liquid nitrogen gasify and volume expansion 700 times, extrude the air out and form vacuum in the can, increase the aluminum can/pet can internal pressure to prolong the canned beverage shelf life and keep good looking for better transportation and store.

Operation Conditions:

1,Supple of Liquid Nitrogen: Regulate to 15 (0.1MPa) and connect to liquid nitrogen pipe.

2,Compressed Air or Nitrogen: Supply to the working of dosing valve. The pipe diameter must be 1/4inch and pressure range is from 50psig to 100psig (3.4 to 6.9 bar). Set the pressure to 50 psig (0.35MPa). Please do not set the pressure too high, high pressure means high impact, it will shorten the lifetime of dosing valve element and internal vacuum pipe.

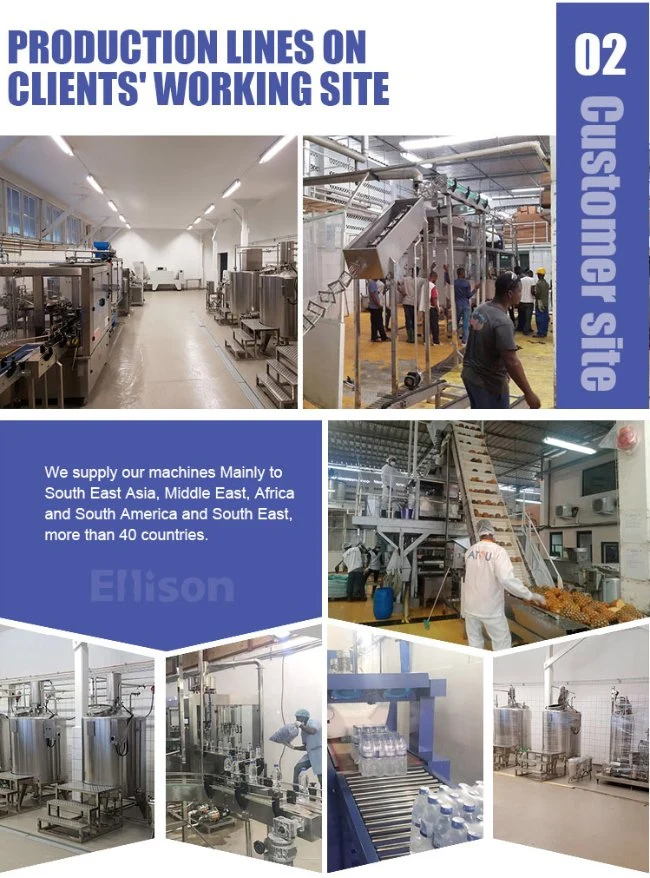

Photos for ref

Features

1,No container no dose and interval dose method in low speed to reduce liquid nitrogen consumption; dosing valve is always open in high speed. Automatic detects high speed or low speed.

2,Vacuum & heat insulation protection

3,Special nozzle care system effectively avoided nozzle frost and ice blockage phenomenon.

4,Liquid-gas separator ensures liquid nitrogen in a ultra cold state, improves liquid phase purity to make the dose more precision and steady.

5,Liquid nitrogen buffer function, effectively control liquid nitrogen bounce splash. Liquid nitrogen dosing amount is steady and ensures can pressure equality.

6,Filter(optional) 10μm to removes particulate pollution

7,Precise dosing liquid nitrogen speed could reach to 300cpm, continuous dosing speed could reach to 800cpm

8,Capacity adjustability and effectively vacuum liquid nitrogen insulation pipe ensures minimum liquid nitrogen consumption

9,Advanced dosing valve ensures transport pure and liquid nitrogen.

10,Lowest outlet pressure of dosing valve ensures minimum liquid nitrogen splash.

11,No frost operating condition.

12,Precise adjustability of dosing amount and dosing time

13,Continuous self-monitoring through alarm indicator

14,PLC control/Touch screen/user-interface language selectivity

15,Could connect liquid nitrogen vacuum and heat insulation pipe, also could provide a complete liquid supply system from liquid nitrogen storage tank to filling production line.

16,Small size and easy to install

17,Diversity machine types ensures to suit different capacity production lines.

18,Apply to all different sizes pet bottles and thin-wall easy open cans production lines

Parameters

| Capacity | 30~400 cans/ min |

| Application | Suitable for can and bottle |

| Voltage | 380 V 50HZ |

| Power | 200w |

| Weight | 100kg |

| Dimension | 1000×600mm |

Package

1, We will help to pack the machines with standard export wooden case package or the wooden pallet;

2, We will help to order the containers from the shipping forwarder;

3, We will help to load the containers;

4, We will deliver containers to loading port;

5, We will send all the shipping documents to client;

Our Service

The sample service

1. we can send you the video of the running machine.

2. you are always welcome to come to visit our factory, and you may see the operation of the machines here . We will make the arrangement to pick you up when you come .

3. If we get the permission of the customer who has brought the machines from us ,we can tell you their contact information, you can go to visit their factory.

Customized service

1. we can design the machines according your requirements(material ,power,filling type,the kinds of the bottles, and so on).

2. at the same time we will give you our professional suggestion.

After-sales service

1. we will provide the bill of load on time to make sure you can get the machine quickly.

2. when you finish the Preparation conditions ,our engineer will go to your factory for the installation, testing and also training.

3. we provide one year warranty with spare parts free.